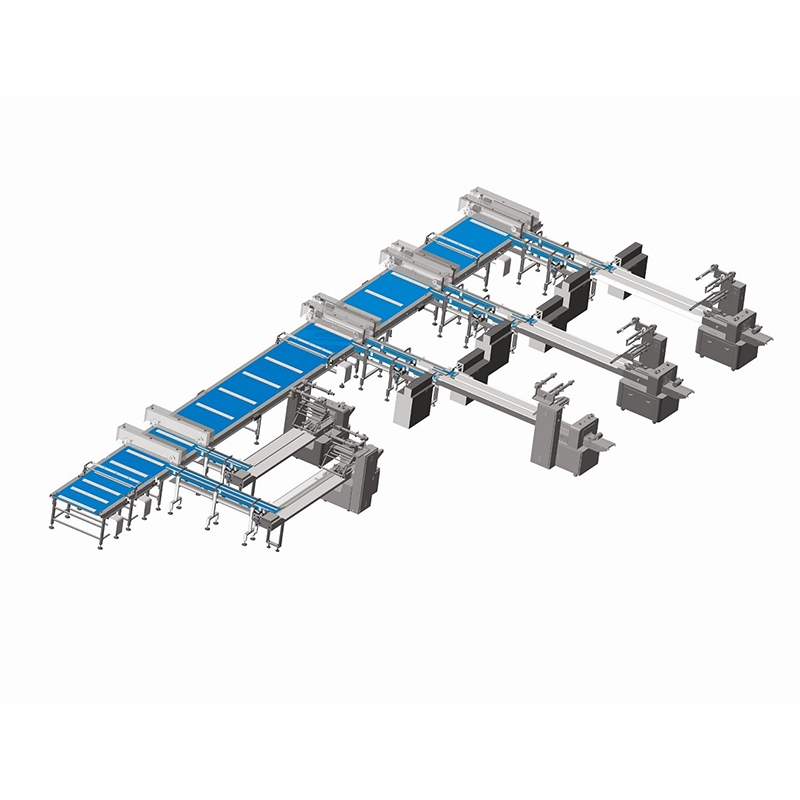

I-Wafer ezenzekelayo yokuPakisha umgca we-L Uhlobo

Inkcazelo emfutshane:

Lo mgca wokupakisha we-wafter ozenzekelayo uyasebenza kwi-wafer kunye nezinye iimveliso zokusika ezifanayo ezinomthamo omkhulu, kodwa ngokulandelelana okulungileyo kunye nokumila rhoqo. Isombulula iingxaki zemveli njengemigama ekufutshane phakathi kweemveliso, ukuguquka komkhombandlela onzima, akulula ukucwangcisa kwimigca, njl.

Iinkcukacha zeMveliso

Iithegi zeMveliso

Iinkcukacha zeMveliso

Le nkqubo yokupakisha ngokuzenzekelayo yenzelwe iimveliso ezine-tray okanye ibhokisi, kwaye lo mgca wokupakisha unokulayisha ngokuzenzekelayo i-tray kunye nokupakisha ngaphandle kokusebenza ngesandla.

Umsebenzi omnye unokusebenzisa imigca emibini, enceda ukugcina iindleko zabasebenzi kubathengi.

Lo mgca wokutya kunye nokupakisha uxhotyiswe nge-deoxidizer okanye i-deoxidizing agent pad feeder, i-tray yokufunxa iyunithi, i-tray yokulayisha iyunithi kunye nomatshini wokupakisha.

Isantya sokupakisha i-tray yokulayisha kunye nomgca wokupakisha yi-100-120 izikhwama ngomzuzu.

1. Ukuqaliswa kweMveliso yeZixhobo zokuSonga eziHolizonti eziziSebeyo ze-Swiss Roll

Le nkqubo yokupakishwa kwe-wafer yinkqubo enemisebenzi emininzi, enokupakisha i-wafer enye kunye ne-multi-wafer. Siye sayila yonke inkqubo yokupakisha ngokwendlela yakho kunye nemibuzo. Esona santya siphezulu sinokufikelela kwiingxowa ezingama-250 / ngomzuzu. Isantya sepakethe yentsapho sixhomekeke kubukhulu.

2. Umsebenzi oPhambili wokuTya ukuPakisha uMshini we-Wafer

Umgca wokupakisha wewafer uquka isilawuli somgama, umva umva, iyunithi yokuhlela ngokuzenzekelayo, kunye nomatshini wokupakisha. Le nkqubo iya kunceda ukulungelelaniswa kwe-wafer auto, ukude, ukuhambisa, kunye nokuhambisa kwiyunithi yokuhlela kunye nokugqiba ukupakisha ukuze kugcinwe imveliso eqhubekayo kunye nocwangco kunye nenkunkuma ephantsi kunye nephakheji elihle. Isitshizi sotywala kunye nokutshaja emoyeni kuyakhethwa.

Isantya sokupakisha umgca omnye unokufikelela kwiingxowa ze-80-220 / min.

Yonke inkqubo yokupakisha ithatha i-220V, i-50HZ, isigaba esisodwa. Amandla ewonke ngama-26KW

Inkqubo yokupakisha ukutya ingasebenzisa iimodeli zokupakisha ezahlukeneyo ngokwemibuzo yemveliso yabathengi.

3. I-Advanteji yeNkqubo yokuPakisha ukutya okuzenzekelayo kwi-Biscuit ye-Wafer

Umgca wokupakisha othe tye oxhotyiswe ngesixhobo sokulungelelanisa ngokuzenzekelayo kunye nesikhuselo sokukhusela. Isixhobo sokuzilungisa ngokuzenzekela sinokuzikhethela.

Ulwakhiwo olulula, ukusebenza lula, ukucocwa okufanelekileyo, kunye nokugcinwa. Uhlengahlengiso olulula kwiimveliso ezahlukeneyo okanye useto lweparameter.

Inkqubo yoLawulo isebenzisa umgangatho ophezulu we-elektroniki, i-PLC ekrelekrele, isikrini esichukumisayo, kunye ne-HMI elungileyo, isebenza ngokulula nangokulula.

Umgca wokupakisha ohambayo uxhotyiswe ngamabhanti esantya ahlukeneyo ukulungiselela izonka okanye iikeyiki ukuqinisekisa isantya esiphezulu ngokuzinzileyo kwaye ufumane ngokuchanekileyo.

Umatshini wokupakisha ukutya okuzenzekelayo kunye nenkqubo isebenzisa insimbi engenasici kunye ne-Nylon baffle, kulula ukuyisebenzisa kunye nokucoca.

Ibhanti ye-PU inokukhutshwa ngaphandle kwezixhobo kwi-1 ngomzuzu kwaye ixhotyiswe nge-hopper ukufumana inkunkuma yemveliso, ekulula ukuyicoca kunye nokugcinwa kwayo.

Isakhiwo soomatshini bokutya silula kakhulu, kulula ukusebenza, silungele ukucocwa nokugcinwa. Uhlengahlengiso olulula kwiimveliso ezahlukeneyo okanye useto lweparameter.

Inkqubo yoLawulo yezixhobo zokupakisha ifilimu yeplastiki isebenzisa umgangatho ophezulu we-elektroniki, i-PLC ehlakaniphile, isikrini esichukumisayo, kunye ne-HMI elungileyo, isebenza ngokulula nangokufanelekileyo.

Siza kongeza i-90-degree turning conveyor okanye i-180-degree-conveyor yokuguqula i-conveyor kwinkqubo yokupakisha ngokuhambelana nokuhlelwa kwefektri yabathengi okanye indawo.

Ukuxhotyiswa nge-meter detector kunye nokukhangela ubunzima, obunokudibanisa ngokuzenzekelayo kunye nenkqubo yokupakisha.

Umatshini wokupakisha ukutya ozenzekelayo owenziwe nge-wafer oxhotyiswe ngesixhobo sokulungelelanisa ngokuzenzekelayo kunye nesixhobo sokuzilungisa esizenzekelayo sebhanti kukuzikhethela.

Umgca wokupakisha unokulungelelanisa ama-wafers (iimveliso) kwaye uhambise kwiyunithi yokuhlela ngokulandelelana ukuqinisekisa isantya esiphezulu ngokuzinzileyo kunye nokuzifumana ngokuchanekileyo.

Ibhanti le-PU lomatshini wokupakisha lingakhutshwa ngaphandle kwezixhobo kwaye lixhotyiswe nge-hopper ukufumana inkunkuma yemveliso, ekulula ukuyicoca kunye nokugcinwa kwayo.

Ulwakhiwo olulula, ukusebenza lula, ukucocwa nokulondolozwa ngokufanelekileyo. Uhlengahlengiso olulula kwiimveliso ezahlukeneyo okanye useto lweparameter.

Inkqubo yokulawula umgca we-wafer isebenzisa umgangatho ophezulu we-elektroniki, i-PLC ekrelekrele, isikrini sokuchukumisa, kunye ne-HMI elungileyo, isebenza ngokulula nangokulula.

Ibhanti le-PU lomgca wokupakisha we-wafer unokusebenzisa ubungqina obuncangathi kumbala omhlophe ngokuzikhethela.

4. Ukusetyenziswa koomatshini bokuPakisha ngokuzenzekela

Inokusetyenziswa ukupakisha ukutya okugqithisiweyo kunye nezinye iimveliso eziqhelekileyo, ezenziwe ngoomatshini bokusika. Idityaniswe nomgca wemveliso yangaphambili ngokutya okuzenzekelayo okanye ukondla ngesandla.

5. Iisampulu zokuPakisha

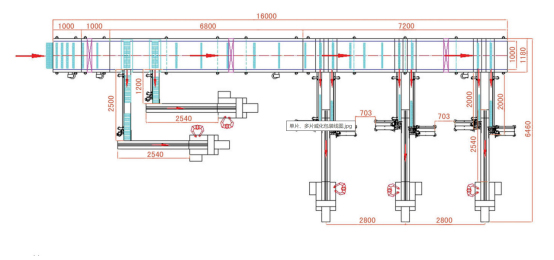

6. Umzobo we-Automatic Packaging Solution

7. Iinkcukacha zeNkqubo yokuPakisha.

(1) Umlawuli womgama

Umsebenzi ophambili wesilawuli somgama kukutsala kumgama wemveliso okanye uzigcine kwimiqolo.

(2) Ukuhambisa umhambisi

Lo mthumeli wokuhambisa isisombululo sokupakisha usetyenziselwa ukuhambisa iimveliso kwimigca yokupakisha eyahlukeneyo. Ubude bala macandelo buxhomekeke kumthamo wemveliso yabathengi okanye kwisakhiwo sefektri.

(3) I-Direction pusher

Isalathiso sesalathiso siqhele ukusetyenziswa kuphela kwinkqubo yokupakisha ye-wafer, enceda ukuguqula isalathiso se-wafer kunye nokuhambisa kumatshini wokupakisha owahlukileyo.

(4) Ibhanti yokugcina

Umsebenzi oyintloko weBhanti yokugcina kukugcina ezo ziqwenga kunye nokunceda ukuhambisa kumatshini wokupakisha, ukugqiba ukupakisha.

(5) I-Servo pusher

Intshayelelo: Le servo pusher isebenzisa kuphela intambo yosapho yokupakisha isisicaba. Ngomyalelo wamagama, ukuba ufuna i-6pcs ngesikhwama (2layer kunye noluhlu ngalunye iziqwenga ezi-3), ke le nxalenye kufuneka ilandele. Ukuba ufuna nje ukupakisha i-wafer enye, akukho mfuneko yala malungu.

Umsebenzi: Owona msebenzi uphambili kukutyhala iwafer yeqela kwi-conveyor ye-infeed, emva koko iphakheji.

(6)Iyunithi yokuhlela

Iyunithi yokuhlela yentshayelelo yenkqubo yokupakisha:

Amacandelo eyunithi yokuhlela aqukethe amabhanti okuhambisa ama-2 kunye ne-5-6 sensors.

Umsebenzi weyunithi yokuhlela:

Umsebenzi oyintloko wale yunithi yokuhlela kukulawula isantya sokutya imveliso, ibekwe kuyo, kwaye idibanise nomatshini wokupakisha ngokuzenzekelayo. Emva kokuba ifumene imveliso kakhulu, isantya sokutya siya kuncipha, ukuba ukungabikho kwemveliso, ngoko isantya sokutya siya kuthetha ngokukhawuleza.

I-advanteji yeyunithi yokuhlela:

Ukunciphisa ukusebenza komntu kwaye uqinisekise ukuba umatshini wokupakisha usebenza ngesantya esizinzile kunye nenkunkuma encinci yemveliso.